Every innovation begins with a question: “Why does it have to be this difficult?”

In workshops across Japan, many seasoned laser machine operators have long relied on the same traditional method to align their cutting nozzles — tape-based centering. They would place adhesive tape under the nozzle, fire a low-power laser pulse, and adjust the head repeatedly until the burn mark reached the center. It’s a skill that demands patience, experience, and a steady hand.

But as the industry matured, this old method began to show its limits. It was time-consuming, fatiguing, and inconsistent — especially for newer operators or those handling multiple machine types. A process that should take seconds often stretched into minutes, with accuracy dependent entirely on human judgment.

At LUMAS K.K., we saw not just a challenge — but an opportunity to rethink alignment itself.

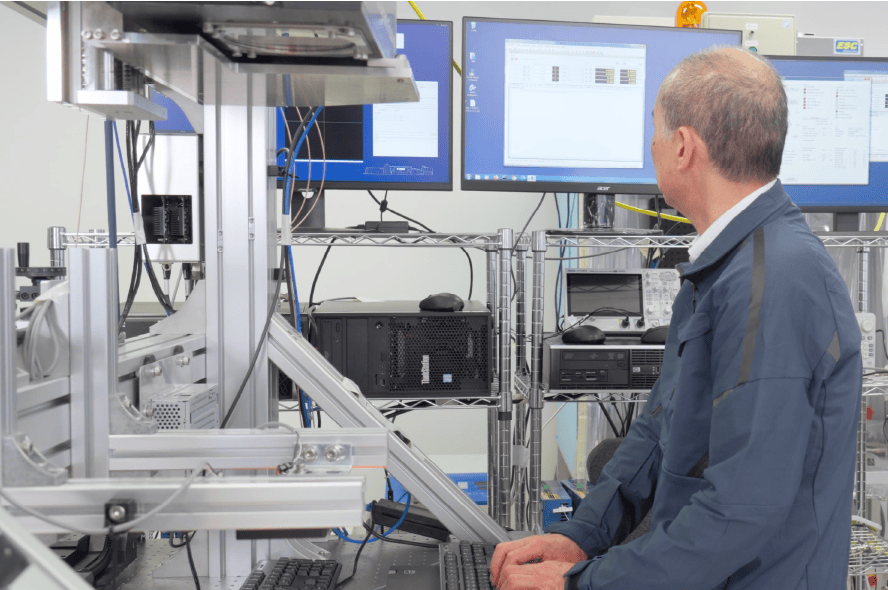

Inside our Tokyo R&D lab, our engineers asked: What if precision could be seen, not guessed?

By merging optical engineering and AI-driven image recognition, we designed a system that could see the laser beam in real time and calculate its offset with sub-millimeter precision. The result became the Nozzle Visual Aligner (NVA) — a compact, camera-based device that uses advanced optics to visualize the laser path and AI algorithms to guide centering automatically.

What once took minutes of trial and error can now be done in seconds — with greater accuracy, and far less strain. Operators no longer need to rely on intuition or eyesight; instead, they see a clear visual overlay that tells them exactly where to adjust.

From concept to prototype, every stage of NVA’s development was guided by a single mission:

To make laser cutting simpler, faster, and more human.

At LUMAS, we believe innovation isn’t just about new technology — it’s about making technology that empowers people. And that’s exactly what NVA stands for.